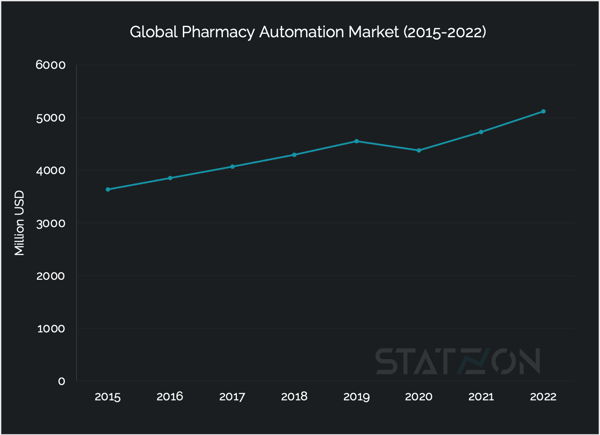

The pharmacy automation market growth has been slow but steady during the last five years. In 2022, the market value was estimated at around USD 5.1 billion. An increase from USD 3.6 billion in 2015, registering a CAGR of 5% based on market research done by Barnes Report. Many other research companies reported a CAGR between 7-8% for the forecast period between 2022-2027. The highly regulated nature of the industry makes it impossible for it to rapidly adopt robotics and automation technology.

Growth in the market is mainly driven by the growing focus on automation to reduce labor costs, the lack of skilled individuals in the field, and increased demand for specialty drug dispensing that requires more complicated techniques compared to traditional prescription drugs.

Source: Barnes Report/ Statzon

Source: Barnes Report/ Statzon

Pharmaceutical robot market size

The use of robotics technology is a big part of pharmacy automation systems. By automating the labeling, filling, and capping of vials, pharmaceutical robots can automate up to 80 percent of a pharmacy’s medication dispensing needs.

Pharmaceutical application takes up around 0.05% of the total medical robot market size. Valued at USD 553 million, the pharmaceutical robotic market is forecasted to grow at 15.7% CAGR to reach USD 2 billion by 2030. COVID-19 pandemic, however, has prompted the adoption of robots at a higher rate than previously predicted in almost every sector, the pharma industry included, enabling companies to overcome labor shortage

According to industry data from the Robotic Industries Association (RIA), there was a 69% increase in year-over-year orders of robotic technology in the life sciences, pharmaceutical, and biomed sectors in North America. The food and consumer goods industry also saw a significant increase of 56%, while the plastics and rubber industry had a 51% increase. This marks the first time that non-automotive sectors have surpassed automotive robot orders, which experienced a 39% increase in 2020.

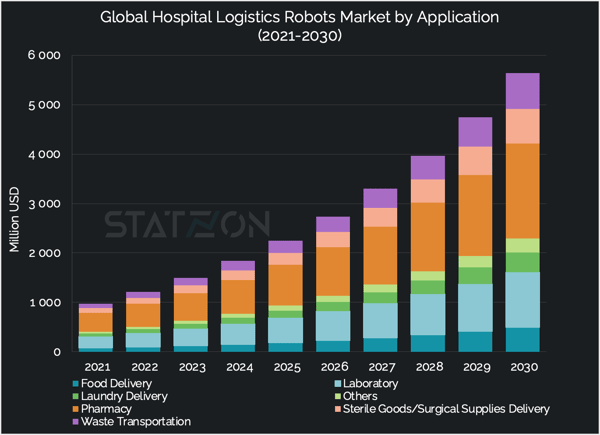

In hospital settings, pharmacy robots are often included under the category of hospital logistic robots. These robots are automated systems designed to assist with various tasks within a hospital setting. They can be programmed to navigate through the hospital, follow schedules, and interact with other systems such as inventory management, medical equipment, hospital management, and elevators, to complete their tasks autonomously. Other robots in this category include delivery robots (surgical supplies, food, and laundry) and waste transportation robots.

Next Move Strategy Consulting evaluated the market size of hospital logistic robots at USD 970 million in 2021. Pharmaceutical and laboratory robots together accounted for 60% of that market value. While pharmaceutical robotics are utilized mostly to automate medication dispensing needs, laboratory robots are programmed to pick up samples from a patient's bedside and deliver them to the laboratory for testing.

Source: Next Move Strategy Consulting/ Statzon

Source: Next Move Strategy Consulting/ Statzon

Robots used in pharmaceutical automation

Traditional industrial robots accounted for around 70% of the total robotic fleet in the pharma industry, based on Magna Intelligence market report, which can be further differentiated into articulated robots (25% of the total robotics system), SCARA (19%), delta robots (16%), cartesian (8%), and dual-arm robots (1%).

Collaborative robots, however, are beginning to take their place in the pharmaceutical robotic market with a 14% growth rate that surpasses traditional robots' 9.8% CAGR. Cobots take up around 30% of the whole pharmaceutical robotics market size. Pharmaceutical companies are likely to bank on collaborative robots to boost packaging, marking, dosing and reduce waste. Not to mention, pharma labs will invest in cobots for pick and place operations to optimize complex tasks.

Cobots are designed to meet the pharma industry’s specifications for accuracy, precision, and hygiene. They are sought-after for their smaller size and programming flexibility, making relocation easier as well as programming for different kinds of tasks.

Cobot applications in pharmaceutical industry

The theory behind cobots is that they work alongside humans. This may be to assist and speed up operations or to carry out a menial task and allow humans in pharma to focus on other areas such as research and development. The main areas where cobots are being used in the pharmaceutical business are as follows:

Dispensing

Cobots can be programmed to identify different types of medicines, recognize pills of different sizes and weights as well as read barcodes. Helped by their gripping mechanism, cobots can select and dispense the correct medicines to the right container. The use of cobots dramatically increased the rate at which a prescription can be ordered and fulfilled.

Assembly of pharmaceutical devices

Cobots with force control, precision grippers, and maybe a vision sensor are perfect for this job. Assembly applications range from putting together bulky parts to fitting miniature objects. Cobots can perform precise, high-speed pick-and-place functions to make the assembly of small items possible. This includes assembly of glass vials with covers and tube coils with end-fittings.

Packaging and palletizing

This is where cobots can help humans by taking over dull and repetitive tasks in the pharmacy. Equipped with a gripper cobots can lift and move items. Their computer vision and machine learning capabilities allow them to adjust to obstacles and irregular timing. The use of cobots in packaging also means minimizing the risk of contamination.

Quality Inspection

Quality control is paramount in the pharmaceutical industry. Cobots can be programmed to handle the many inspection steps from physical stress testing of medical products to automated scanning with inspection sensors. As robots do not lose focus or get tired, they can maintain the same precise standard at all points of quality inspection process.

Sorting of medicines and medical supplies

This job includes tasks like tray stacking which is made possible for cobots thanks to their 3D vision calibration. A cobot can use a 2D picture of an object to determine a 3D shape. This can allow it to lift and stack trays. It can also remove and replace items from a tray.

Machine Tending

Cobots are only a part of the whole pharmaceutical automation system. Many automated and semi-automated machines are widely used in the system and these machines often still need human intervention for loading and unloading items into and out of the machines. A task that can now be replaced by cobots.

Source: Statzon, automation.com