3D printing is still an emerging technology, but it is one of the core pillars of Industry 4.0. Also known as additive manufacturing, 3D printing is a technique of building a 3D object based on a computer model, often created in programs such as CAD or similar. These computer models are often "printed" in layers using a material such as a polymer, ceramic, rubber, or metal that functions as “ink” for the printer, resulting in a fully tangible 3D object.

Thanks to 3D printing, factories can be more adaptable to meet the demands of a market that is becoming more unpredictable and demanding. Customization in small batches is now made possible by 3D printing in a cost-effective way. 3D printing also allows the ability to test concepts inexpensively through trial and error and a much faster time to market than traditional manufacturing.

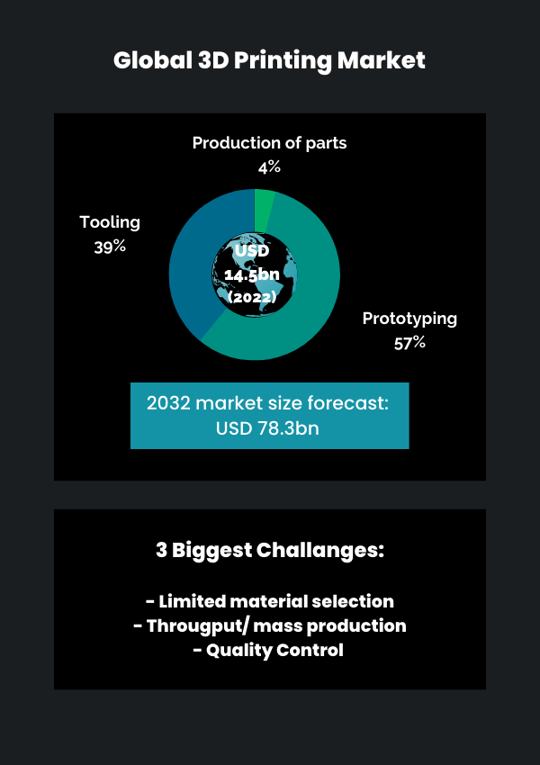

Global 3D Printing Market Size

Markets and Markets estimated the global 3D printing market size will increase from USD 12.6 billion in 2021 to USD 34.8 billion by 2026, growing at a CAGR of 22.5%. Many factors play together in encouraging this growth of the market. Some of the prominent ones are the rising demands for customized products, the push for faster product production at a lower cost, and government investment in 3D printing R&D.

Another market analysis from Apollo Research forecasted the 3D printing market will grow from USD 14.5 billion in 2022 to 78.3 in 2032, registering a CAGR of 18.4%. For the application segmentation, the market size is differentiated into three groups: production of parts, prototyping, and tooling. Market share percentages for the three segments in 2022 are 4%, 57%, and 39%, respectively.

Although 3D printing is widely adopted in the industrial sector, it continues to gain popularity among hobbyists and innovators. At the individual level, 3D printing is used for domestic and personal purposes, while in education settings, it is used for conducting technical training.

Industrial Applications of 3D Printing

Aerospace and defense

The Aerospace 3D printing market reached USD 1.9 billion in 2021. 3D printing enables the creation of complex geometric designs with lighter weight. An aircraft's weight can substantially impact its payload, fuel use, and carbon dioxide emissions.

Automotive

Rapid prototyping is probably the key purpose of 3D printing usage in the automotive industry. Prototyping offers a way to test and validate parts before they are manufactured. A quick and cost-effective design and production of parts can be achieved using 3D printing technology. Customized parts production using 3D printing is also an emerging trend. For example, aluminum alloy can now be used with 3printing to produce exhaust pipes.

Medical

3D printing excels at producing patient-specific devices such as prosthetics and implants. These devices can be produced faster and more affordably than with traditional manufacturing methods. The 3D printing market for medical devices was valued by Markets and Markets at USD 2.3 billion in 2021.

Robotics

3D printing capabilities allow detailed and complex robotic parts to be manufactured quickly. Other crucial factors like reduced weight and customizability can also be achieved, especially when producing parts like robot sensors and grippers.

Construction

3D printing in construction has a wide array of applications in the construction sector. It can be used in extrusion of material, powder bonding, and additive welding.

The Dutch city Nijmegen has the longest 3D-printed bridge in the world, built in 2021. The bridge was designed on a computer and printed piece by piece before being assembled on site. The whole process used 50% less material as the printer only deposits concrete where it’s needed for structural integrity.

Three main areas of challenge

Limited material selection

Not all of the materials that can be used in the production of an object are available for 3D printing. Most 3D printers are designed to process polymers, metals, composites, ceramics, or glass. Some metals and polymers cannot be temperature-controlled to be used in 3D printers. Material selection is a complicated process with trade-off calculation involved in balancing product requirements against its material’s properties. Using different materials during prototyping and production will add to the complexity.

Throughput

Mass production was never the intention of 3D printing. Instead, its ability to create complex shapes has been limited to small batch manufacturing. Key players in the industry have been developing a system that can rapidly produce objects or results.

Companies like HP, GE, and Desktop Metal are currently experimenting with low-cost metal powders that can be used to 3D print large numbers of parts in a single job. This will disrupt the cost structure for metal 3D printing in the future.

Quality Control

Each object created by 3D printing is different. Different angles of working will lead to different results, and because 3D printed objects are built up of many layers, it is difficult to impose quality control for each of the layers. The only way to do it is probably by undergoing a CT scan for each object, which is an expensive and time-consuming process.

Newer and cheaper CT-scanning systems are coming to the market, fortunately. But there are companies like ANSYS that have developed software that can anticipate any defects occurring during the printing process and compensate for them. Other companies like Sigma Labs and Additive Assurance have created hardware to monitor the build chambers of metal 3D printers to detect errors.

|

|